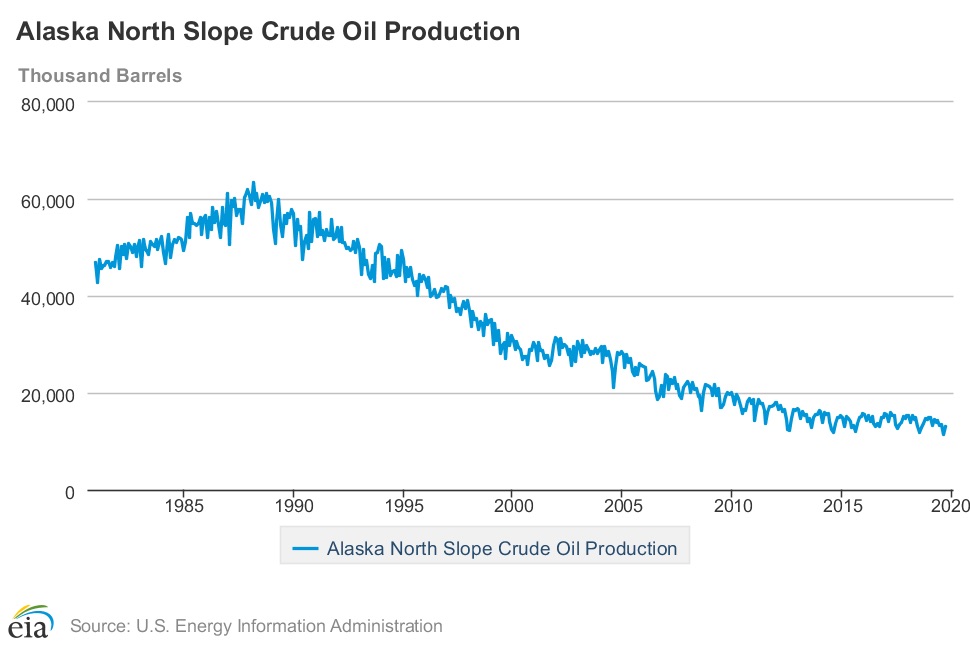

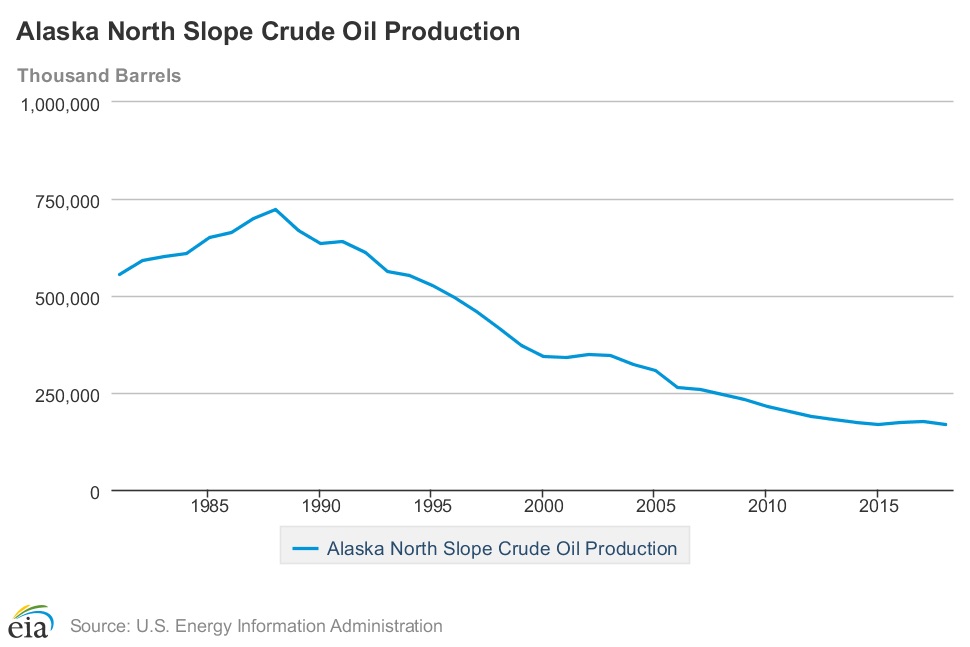

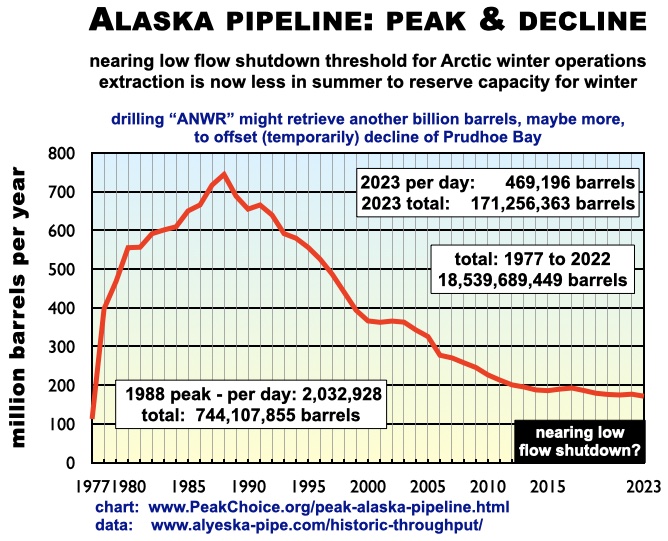

Alaska pipeline 1988 peak: 2 million barrels / day

In 2019, oil extraction dropped below a half million barrels a day, nearing "low flow" shutdown

neither drilling advocates nor environmentalists discuss depletion

- end of the pipeline

- news

- Arctic National Wildlife Refuge & National Petroleum Reserve

- US Energy Info. Admin.charts

The pipeline has a minimum flow level required to keep the contents above freezing so they can be pumped from one side of Alaska to the other in the Arctic winter. Estimates vary but around three hundred thousand barrels a day is a good guess for the low flow shutdown threshold. The last barrels on the North Slope will not be extracted - some of the remaining reserve will be left in the ground, inaccessible.

The pipeline has a minimum flow level required to keep the contents above freezing so they can be pumped from one side of Alaska to the other in the Arctic winter. Estimates vary but around three hundred thousand barrels a day is a good guess for the low flow shutdown threshold. The last barrels on the North Slope will not be extracted - some of the remaining reserve will be left in the ground, inaccessible.

The Alaska Pipeline requires a tremendous energy input to pump the oil from Prudhoe Bay (in north Alaska) to the harbor terminal at Valdez. While the energy input into the system is dwarfed by the energy density of the transported oil, it is a factor to consider as the oil fields dwindle further. The pipeline has heaters along the route to keep the contents above freezing, which lowers the "Energy Return on Energy Invested" (EROEI).

The pipeline consortium maintains a web page that discusses some of the energy required to keep the pipeline functioning at www.alyeska-pipe.com/Pipelinefacts/PumpStations.html Drilling for oil in Arctic conditions requires more energy than oil drilling in warmer climates, especially if the oil is closer to the surface and under higher pressures (ie. most of the Middle East fields).

related pages:

- 55 mph speed limit would reduce US oil use more than Alaska pipeline

- Offshore Drilling on a Swift Boat: geology is more important than the politics of blame

- Vice President Sarah Palin? cementing the official illusion about Alaskan oil

Aleyska Pipeline company summary:

www.alyeska-pipe.com/historic-throughput/ (January 11, 2024)

TAPS throughput levels have had their ups and downs over 44-plus years of operations. Less than three years after oil first entered the pipe on June 20, 1977, TAPS had already moved 1 billion barrels. In 2019, Alaska celebrated TAPS passing the 18 billion barrels milestone. Other highs: In 23 years, TAPS daily throughput averages were above 1 million barrels per day (bpd); throughput peaked in 1988, averaging an astonishing 2,032,928 bpd. The lows: In 2019, TAPS daily throughput landed below 500,000 barrels for the first time (490,366) and dipped further in 2020 (480,199).

Less oil in TAPS means slower-moving and colder oil, which creates complicated operational challenges. Alyeska and its owner companies continue analyzing the risks, options and challenges of declining throughput while creating mitigations and validating other potential steps through laboratory and field tests.

November 30, 2018 - pipeline escaped earthquake damage

On November 30, 2018 the Anchorage area experienced a magnitude 7 earthquake that destroyed buildings, roads and bridges. Fortunately there were no fatalities or serious injuries, but the region's critical infrastructure suffered damage that will take money, labor, fossil fuels, and minerals to repair.

The pipeline's terminal was not in the maximum shaking zone.

A magnitude 9 earthquake shook that region in 1964, causing far worse damage including a tsunami that wrecked Valdez, where the pipeline terminus is today. This tsunami also killed a few people in Crescent City, California - there was no tsunami warning system then and it arrived there at night, making warning and evacuation impossible.

A rarely reported upcoming problem with the pipeline is low flow shutdown. Its flow peaked in 1988 and is now three fourths less, and barely pumps enough to keep the contents liquid in the Arctic winter. When it's over, there will be major energy disruptions on the west coast that we are totally unprepared for either logistically or psychologically. I assume the Trumpsters will loudly proclaim the shortages are the fault of the "stop drilling" crowd and will have a lot of people believing that. Practical approaches - system wide "Transition Town" and permaculture, cooperatives, etc. would be needed to mitigate this impact. Protests don't get us there.

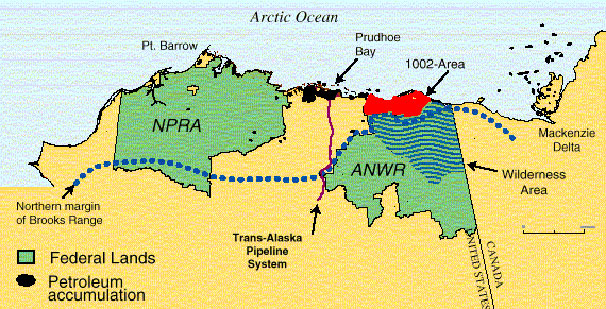

Prudhoe Bay has pumped over 17 billion barrels since the pipeline opened. The National Petroleum Reserve – Alaska in northwest Alaska, opened to drilling exploration by the Clinton Gore administration in 1998, was originally thought to have ten billion barrels. Current estimates are under a billion. The Arctic National Wildlife Refuge might have a billion barrels, some estimates are higher but could be boosterism.

It's not a secret that the pipeline is declining toward low flow shutdown, but there has been little media coverage and there's almost no public awareness.

Rebuilding roads, power lines and other critical infrastructure in the aftermath of today's quake will require fossil fuels and minerals. It's hard to make steel and concrete and asphalt without these inputs. Same with fighting forest fires or rebuilding damaged communities. If we were smarter as a society we would require the rebuilding to be hyper efficient, passive solar designed, and other practices more appropriate for the lower energy flow future we are entering due to depletion. I've been talking about this for nearly two decades in Ore-is-gone and have not found politicians, newspapers, civic organizations, environmental groups, anyone who is already informed (with the exception of a few insiders with specialized technical knowledge). A native friend who used to live in Anchorage told me a few years ago that it's not a topic he has ever seen discussed there. I hope everyone will accept that there was only so much oil put in the ground by geological processes, Jesus, Allah or the Flying Spaghetti Monster (depending on one's belief systems) and that it was a once time gift of Nature, squandered quickly. Otherwise, we are likely to see scapegoating and anger that would likely make a rational, cooperative response to the downslope impossible to realize.

Damned if we drill. Damned if we stop.

http://www.npr.org/2017/06/24/533798430/alaskas-40-years-of-oil-riches-almost-never-was

Now, Alaska's long dependence on oil may be coming to an end.

"You have a state where oil had paid for almost everything and suddenly the oil revenue – most of it — has evaporated," said economist Gunnar Knapp, former director of Institute of Social and Economic Research at University of Alaska Anchorage.

After four decades of production, it's getting harder to pump oil out of Prudhoe Bay. The field has been in steady decline since the mid-1990s. The amount of oil flowing through the 800-mile trans-Alaska pipeline each day is now about a quarter of what it carried at its peak in the 1980s. That, coupled with a crash in oil prices, means the state faces an uncertain future. Today, Alaska state lawmakers are battling over what to do next, and narrowly averted a government shutdown this month.

Alaska's 40 Years Of Oil Riches Almost Never Was

June 24, 2017 7:00 AM ET

Heard on Weekend Edition Sunday

ELIZABETH HARBALL

alyeska-pipe.com/NewsCenter/HeadlineStories

"Cold oil a hot topic during winter"

As oil throughput declines, TAPS faces new and complicated challenges. One of the most complex is maintaining crude oil temperature in the pipeline at around 40 degrees during the winter. This provides a safe operating buffer above 31 degrees, at which point trace amounts of water in the oil can begin to freeze. Heat input along TAPS is critical during cold weather; the hotter the oil, the lesser the chance of ice formation during extreme cold weather events or unplanned pipeline shutdowns. Ice in the pipeline can pose risks to mainline check valves, instruments, mainline pumps and maintenance pigs.

Each winter between October and March, Alyeska's Operations Engineering and the Operations Control Center constantly analyze temperatures along the pipeline and look at weather forecasts to optimize heat input.

"The effort requires a mix of science and intuition to maintain the target temperatures for the pipeline system," explained Mike Malvick, Flow Assurance Advisor with the Flow Assurance Team. "And it's a system that has a lot of thermal mass and a transit time that exceeds two weeks."

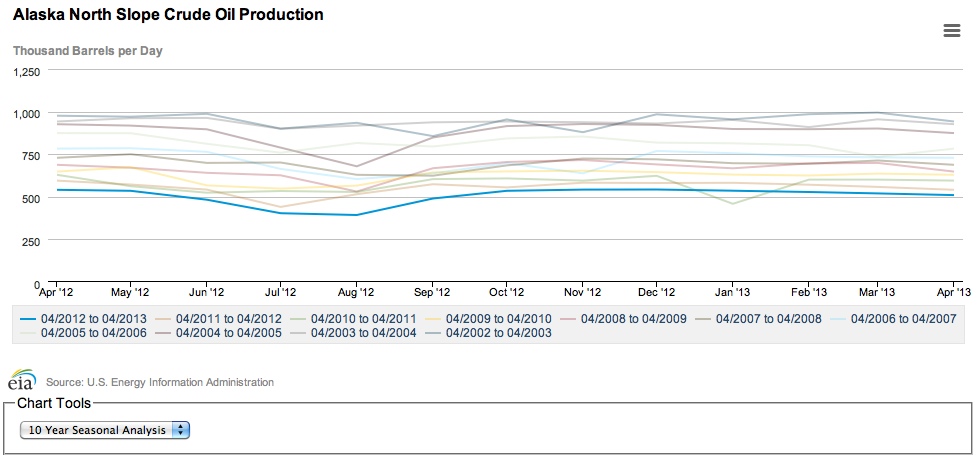

TAPS oil temperature is a function of pipeline throughput and the time the oil spends in the pipeline. At its peak in 1988, TAPS throughput was more than 2 million barrels a day. At that rate, oil traveled from Pump Station 1 to Valdez in 4.5 days and was as hot as 120 degrees. Freezing water and wax accumulation weren't concerns.

Oil now leaves Pump Station 1 at approximately 110 degrees and experiences a significant drop in temperature almost immediately upon departing, then continues cooling as it travels to Valdez. Today's throughput is around 530,000 barrels a day, taking 18 days to travel to Valdez. On Monday, January 26, oil departed Pump Station 1 at 106 degrees with an ambient temperature of 17 below zero. By the time the oil traveled 100 miles south to Pump Station 3, the environment had drawn 51 degrees from its natural temperature. Near the Yukon River, temperatures were around 50 below zero. In Fairbanks, temperatures hovered around 40 below. Without heating assistance, the oil would eventually cool below 31 degrees before reaching Valdez.

http://energyskeptic.com/2015/when-will-the-alaska-pipeline-turn-into-an-800-mile-long-popsicle/

When will the Alaska pipeline turn into an 800-mile-long Popsicle?

Posted on August 15, 2015 by energyskeptic

[Below are excerpts on the Alaskan pipeline from Rust: The Longest War by Jonathan Waldman. This is a great book, yet leaves so many possible rust stories uncovered, that I hope Waldman writes Rust II (or any other topic — will certainly read his next book whatever it is). Alice Friedemann www.energyskeptic.com ]

Officially, Neogi is the pipeline’s integrity manager. He is responsible for keeping the pipeline intact, whole. Most pipeline operators employ integrity managers, but most pipelines are not like the Trans-Alaska Pipeline System. From Prudhoe Bay to Prince William Sound, TAPS stretches eight hundred miles, which leaves Neogi accountable for one of the heaviest metal things in the Western Hemisphere, through which the vast majority of Alaska’s economy flows. Daily, the four-foot steel tube spits out $50 million of oil.

Four technicians from Baker Hughes, the pig’s manufacturer, wrapped up a third day of checking and double checking and triple checking its componentry. Among other things, in the front segment of the pig, between two yellow urethane cups, they checked 112 magnetic sensors mounted in between 112 pairs of magnetized brushes. These sensors would detect the magnetic field induced in the pipe as the pig, propelled by the flow of oil, traveled through it. Given any kind of anomaly in the half-inch steel—a pit, a ding, a thin spot—the field would change, and the sensors would capture this and record it on a hard drive. Inch by inch, the sensors would capture this information; Neogi hoped they would capture all seven billion square inches of the pipe. That’s 1,200 acres. Using all that data, Neogi would determine the most vulnerable spots on the pipeline, dig them up, and repair them before they became leaks.

No matter how extensively the technicians double checked, even the most advanced pig can’t perform its inspection if the wall of the pipe is covered in wax. Wax, a natural component of crude oil, keeps the magnetic brushes and sensors off the steel wall. The consistency of lip balm or mousse, it plugs up caliper arms that measure the shape of the pipe, and snags odometer wheels. Wax renders smart pigs senseless, leaving them blind, dumb, and amnesiac. Nor can a pig survive a violent voyage. Too fast, and sensor heads melt or crack. Too rough, and the magnetizing brushes wear down. Too jarring, and the universal joint between the pig’s two segments comes apart, wires snap, and power to the magnetic flux sensors is cut off. Poof goes the data, months of work, and millions of dollars—leaving engineers with a pipeline in indeterminate condition, regulators unhappy, and the public at risk. Wax accumulates when the oil cools below 75 degrees, and long, slack sections, where the pig can barrel down mountain passes at high speed, manifest themselves when there’s not much oil flowing through the pipe. Neogi was well aware that it was winter, and that the flow of oil through TAPS was as low as it had been. It was not the best of times to pig.

On account of wax and low flow rates, in the last dozen years, half the smart pig runs have failed.

More recently, a pig was sucked into a relief line at a pump station midway down the line. That the relief line was only sixteen inches in diameter, and guarded with pig bars, was not a sufficient deterrent to the forty-eight-inch pig. This has happened at least a half dozen times. When it happened in 1986, and the pipeline was shut down while the pig was extracted, that meant more than a quarter of the nation’s oil wasn’t moving toward California. Pigs have made it all the way to Valdez, Alaska, only to be ingested in relief lines there. Other pigs have damaged the pipeline, or gotten stuck in it and been destroyed during their extraction.

They planned to launch the tool at seven in the morning, exactly twelve hours behind a red urethane pig of lesser intelligence. That pig, like a giant squeegee, was scraping the line clean. It was the last of nine such scraper pigs that, by Neogi’s design, had been shoved down the pipeline in the previous six weeks. Neogi had kept track of how much wax these pigs had pushed out in Valdez, and graphed it. From 1,200 pounds, the mass had dropped to 400. The line was as clean as it was going to get, primed for inspection. It was ready for the smart

For two decades, the Prudhoe Bay oil fields—Sadlerochit, Northstar, Kuparuk, Endicott, Lisburne—have been declining steadily. Yearly, immutably, they produce 5 percent less oil. The result is that TAPS now carries one quarter of the oil it was designed to carry. It comes out of the ground colder than ever and flows more slowly toward Valdez. Crude used to make it to Valdez in four days, as if running seven-minute miles. Now it walks. Enroute, it cools off even more and, as it does so, deposits more wax on the pipeline. A doctor would call the pipeline arteriosclerotic. While a pipeline waxes, its diameter wanes. Declining throughput makes things difficult for Neogi, but it makes them even more difficult for agencies estimating the pipeline’s lifespan.

The pipeline was designed to survive as long as the oil fields. Lest it clog, it must stay warm, which means that it must remain full of flowing oil. In a perverse symbiosis, the pipeline needs the oil as much as the oil needs the pipeline. As a result, while the consortium of agencies that oversees the pipeline has written that it “can be sustained for an unlimited duration,” Alyeska figures that it’ll survive until 2043, and the state of Alaska figures that it’ll expire a bit sooner. Private consultants, hired to estimate the life of TAPS, mention only “the future” and write of “diligent upkeep” in passive sentences. The estimates all couch what nobody wants to say: the pipeline, once the largest privately funded project in America, and one of its greatest engineering achievements, is now an elderly patient in intensive care.

The companies that built the pipeline foresaw such a future and tried to avoid it. In the immediate aftermath of their 1968 oil discovery, they considered every alternative to a pipeline. They considered extending the Alaska Railroad to the North Slope, until they realized that it’d take sixty-three trains, each one hundred cars long, every day, to ship their oil. They considered trucks, calculating that they’d need nearly the entire American fleet in addition to an eight-lane highway. They looked into jumbo jets supplied by Boeing and Lockheed, turning away when it became apparent that their air traffic would exceed the combined air traffic of all the freight in the rest of the country by more than an order of magnitude. They looked into blimps. They commissioned the world’s largest icebreaking cargo ship, and after it got stuck in the Northwest Passage, they seriously considered using a fleet of nuclear submarines to ship the oil, under Arctic ice, to a port in Greenland. Reluctantly, out of alternatives, they settled on a pipeline.

On most other pipelines, “events” or “incidents” or “product releases”—what the rest of us call leaks or spills—are most often caused by third-party damage. By this, the industry means accidents. Heavy equipment is usually to blame; pipeline ruptures are most often caused by collisions with bulldozers and backhoes. On TAPS, since there’s so little construction across the vastness of Alaska, the risk of accidental third-party damage is low. Natural hazards, on the other hand, present threats in abundance. Earthquakes, avalanches, floods, and ice floes all threaten TAPS. But what really keeps Alyeskans up is corrosion. It’s the number one threat to the integrity of the Trans-Alaska Pipeline. On account of that threat, the pipeline was outfitted with the greatest corrosion-protection features of the era. Its principal protection was its coating: paint. As a backup, a zinc strap the size of a wrist (a giant anode) was buried under the pipe. Though TAPS was, boldly, called rustproof, the defense proved insufficient. Like all coatings, the one on TAPS proved vulnerable—but Alyeska didn’t learn quite how vulnerable for a dozen years. When it did, the company beefed up the pipeline’s corrosion protection with 10,000 twenty-five-pound bags of buried magnesium anodes and a cathodic protection system consisting of a hundred-odd rectifiers spitting a low voltage into the pipe.

Because rocks resist current, the cathodic protection system doesn’t work well in rocky areas, leaving corrosion engineers to their final tool: coupons. On the pipeline, a coupon is a one-inch square of steel, connected to it and buried along it, serving as a surrogate. Alyeska has about eight hundred of them. But coupons don’t prevent corrosion; they just help engineers monitor it.

In a way, monitoring is Alyeska’s second line of defense, and Alyeska does a lot of it. Like all major pipelines, TAPS is monitored by leak-detection software, which compares the flow of oil going into the pipeline with the flow coming out the other end, and also scans for sudden pressure drops. But unlike other pipelines, it is also monitored regularly by pilots using infrared cameras to hunt for signals that the hot oil has escaped into the cold Alaskan earth, as well as by “line walkers” who hunt for dark puddles and squishy tundra along the pipeline, and by controllers watching an array of hydrocarbon-detecting and liquid-detecting and noise-detecting sensors shoved into the ground alongside it. And then there are the dozen state and federal agencies looking over the shoulders of the thousand people operating the pipeline, making it the most regulated pipeline in the world.

But because a smart pig is the only way for Alyeska to determine if its pipeline is about to spring a leak before it has actually done so, and because Alyeska operates under more regulatory scrutiny than any other operator, it sends smart pigs down the line nearly twice as often as any other pipeline operator. It employs a smart pig once every three years, and has been doing so since long before federal pipeline laws stipulated it. Thanks largely to smart pigs, TAPS hasn’t suffered a corrosion-induced leak since it began operating in 1977.2 Over its first thirty years, Alyeska reviewed nearly 350 potential threats to the pipeline, including dents, wrinkle bends, weld misalignments, ovalities, gouges, and corrosion pits. The majority of these problems were found with smart pigs.

Keeping the pipe clean has become a priority nearly as great as keeping it whole, because the latter depends on the former. To keep it clean, Alyeska sends cleaning pigs south weekly. The company keeps a fleet of a dozen such pigs at a maintenance yard in Valdez, and in a perpetual relay, these pigs go back and forth: up the haul road, down the line. The managerial pigs—the smart ones—wait patiently while these janitorial pigs stay busy.

Before the last smart pig run, Alyeska sent a janitorial pig south every four days for a month. When these pigs pop out in Valdez, they usually push out ten or twenty barrels of wax. In the pig mobile, they go straight to the pig wash. The wax, a hazardous material, is collected in barrels and shipped out of state. Once, not many years ago, after the pipeline wasn’t pigged for six weeks, a pig pushed out forty-seven barrels of wax. Beneath all that wax, on account of corrosion, the one-billion-pound pipeline loses in the vicinity of ten pounds of steel a year: the same as an old Ford. Most of that metal loss is on the outside of the pipe, where it’s buried. The inside is, well, nicely oiled. The exception is inside pump stations, where the pipe branches through valves and turbines. In deadlegs—hydraulic culs-de-sac, where oil sits stagnant—microbial-influenced corrosion is a threat. If corrosion struck uniformly, such that the pipeline lost metal evenly and consistently, maintaining it would be vastly easier. After a thousand years, 99.999 percent of the pipe would still be there, sans weak spots. But rust doesn’t work like that. It concentrates in relatively few places, begetting more rust. Alyeska responds only to those places that present severe integrity threats. It looks at spots where 35 percent or more of the pipe’s wall thickness is gone, and where metal loss leaves the pipe at risk of bursting, which it determines from a formula developed by the American Society of Mechanical Engineers.

To the pipeline, though, ravens pose a greater threat. Ravens pick at the pipe’s insulation, and then water gets in. Alyeska spent millions installing bands around the seams of the insulation, and the ravens persisted, outsmarting engineers.

the flow of oil through TAPS decreases, pigging will become drastically more difficult. Below 400,000 barrels per day, it will become impossible to tightline Atigun Pass, because there’s only so much oil a controller can store in the tanks at Pump 1 before he runs out of emergency wiggle room. By then, the slack section on Atigun Pass will be over three miles long. Below 350,000 barrels per day, the “slippage factor” of a cleaning pig will prevent it from scraping the line effectively. With the bypass necessary to keep the wax ahead of it in a slurry, there won’t be enough force to push the pig forward. Alyeska will also need to run them more frequently—as frequently as during this run’s cleaning regimen—and this makes controllers nervous. Meanwhile, by 2015, the small percentage of water entrained in the oil will drop out and begin flowing in a separate layer on the bottom of the line. Collecting at a dozen low spots, it could freeze. In so doing, it could disable check valves or halt pigs. At a flow rate of 400,000 barrels per day (expected by 2020), a pig arriving in Valdez could be pushing a slug of water one third of a mile long. Alyeska may need a new type of pig to push out the water, because water will also corrode the pipeline. Compounding matters, lower throughput will make it harder for controllers to detect leaks.

It was the closest that TAPS had ever been to becoming an eight-hundred-mile-long Popsicle. This is Alyeska’s great fear, its “worst-case event.” Declining throughput may necessitate frequent cleaning pigs, complex operating procedures, smarter and tougher pigs, and increased maintenance—but these are nothing compared with the seizure of the pipeline. North Slope crude gels at 15 degrees. It gets so thick that pumps can’t push it. It becomes thixotropic, like quicksand. For whatever reason—a power outage, say—if the oil sits in the line too long, at the wrong time of year, the threat of the big Popsicle looms. In January 2011, the oil cooled to 25 degrees. The threat is critical.

Alyeska’s former president told Congress that at the flow rate expected in 2015, nine winter days of shutdown could spell the ultimate end of the pipeline. If the oil gels, there will be no recovering from it. The threat makes explosions and even leaks seem trivial. It’s a game ender. It’s because of this conundrum that drilling in the Beaufort and Chukchi Seas is of such importance to Alaska, Alyeska, and Alaskans. Those rigs will tie into the Alaska pipeline, feed it their oil. Sure, residents will get annual dividends, and Alaska will receive billions in royalties and taxes that fund pretty much everything in the state. But it’s the long-term future of the state on the table.

The sooner that someone turns around the two-decade saga of declining throughput, keeping the pipeline from turning into a giant Popsicle, the easier those concerned with the integrity of the pipe will sleep. In the meantime, if TAPS leaks for some reason, and the public withholds forgiveness, the resultant delay in offshore drilling could portend the end of the line. That’s what Neogi was implying when he mentioned the impact on future drilling. A big spill could delay offshore drilling in the Beaufort or Chukchi Seas for two decades, and this could spell the end of the line. End of the line would be the end of the state of Alaska, and not exactly beneficial to the economy of the other forty-nine states in the union. Precarious is the future of the pipeline, and high are the stakes in which Neogi and the integrity management crew operate.

www.postcarbon.org/blog-post/165463-alaska-and-energy

Alaska and Energy

Posted Oct 26, 2010 by Richard Heinberg

During my recent visit to Anchorage, Alaska to speak at that city's Bioneers satellite conference, the friendly locals seemed eager to educate me about their local energy issues. Some of what I learned struck me as important to share with a wider audience.

Alaska is, of course, a huge energy exporter. Crude from the North Slope saved America's energy bacon back in the '80s, helping to lower world oil prices and bankrupt the evil Soviet empire. Production there has declined from a peak of over two million barrels per day to only 600,000 or so today. Once the flow drops below 500,000 barrels, there will be problems with icing in the Trans-Alaska Pipeline system. Not good.

The state's economy is based almost entirely on resource extraction. Everyone gets a check annually from the Alaska Permanent Fund, set up in 1976 primarily by the efforts of then Governor Jay Hammond. High oil prices mean big dividends: in 2008-2009 extra-large payouts made Governor Palin look good to her constituents, though she was in no way responsible.

Alaska has enormous opportunities for renewables—wind, microhydro, geothermal, tidal, even solar. But these are far from being adequately developed, and progress in that direction will take time and lots of investment—a dramatically higher pace of investment than is currently evident.

Anchorage (by far the largest city in the state) faces a particular challenge with natural gas: currently nearly all houses are heated with gas, but supplies from Cook Inlet will run low in two years, even sooner with an abnormally cold winter. Most options to replace current sources (more drilling, LNG, alternative energy) will take longer than two years to develop.There is no serious planning for what to do about this.

Then there is the situation of the native villages. On one hand, the indigenous peoples of the north might seem well placed to weather the changes ahead as industrial society succumbs to peak oil, peak coal, and peak gas: they have cultural traditions of self-sufficiency, small populations relative to land area, and access to lots of wild protein on the hoof (moose, caribou). However, as James van Lanen of Alaska Department of Fish and Game wrote to me in an email just the other day:

"Alaska Native villages are in a very precarious situation. These remote villages are only accessible by motorized travel via air or watercraft. They are entirely dependent upon fossil-fuel systems for goods and services: food, heat, health care. They have no contact with the outside world without fossil fuels.

"Some villages obtain more of their food resources from wild sources than others. It would be safe to say that on average 80% of the protein consumption in a village is from wild sources. Berries and Plants supplement some part of the overall diet but this is small. The two important things to consider are (1) much of the food consumed comes from industrial sources and is shipped in via small aircraft and (2) wild food harvests are currently almost entirely fossil-fuel dependent (there is a well-embedded 'machine culture' in native villages; I believe that there is no extant ability to obtain significant amounts of wild foods without the use of machines)..."

"Peak Energy will hit Alaska villages sooner and more intensely than many other places. Fuel is already up to $9 per gallon in some places. As it becomes uneconomical for current supply operations to continue the industrial resources these villages rely on will fizzle out."

"Most village people are aware of their complete dependence upon fossil fuels. Many elders foresee a future collapse due to increasing costs and modern dependence. However, there is no general awareness of the phenomenon of Peak Energy in these communities. There is no awareness that the entire system may break down. Alaska villages desperately need to become educated in what we are facing."

I came away from my too-brief sojourn in Anchorage with both a deep appreciation for this land of great natural beauty, contrasts, and extremes, and an equally deep concern for how Alaskans will deal with their enormous energy challenges. Some of those challenges are going to present themselves forcibly in the very near future.

http://money.cnn.com/2008/05/01/news/companies/hunt_for_oil.fortune/

LAST UPDATED: MAY 3, 2008

Hunting for oil beneath the ice

There's a new rush for petroleum from Alaska to the North Pole. Can ConocoPhillips and other energy giants find another Saudi Arabia under the ice?

By Barney Gimbel, writer

The folks at Conoco surveyed this slice of barren land about a decade ago. But times are a bit desperate up here in North America's largest oil region, and they've come back. "We're looking to see if we left anything behind," says Jim Darnall, an acquisition geophysicist for ConocoPhillips, as he brushes ice off his bushy gray beard. "We're trying to milk this field anyway we can."

Is this what America's late-20th-century oil paradise has been reduced to - the petroleum equivalent of rooting for loose change in the cushions of a sofa? U.S. crude production is at its lowest since 1949, and nowhere has that decline been steeper than in Alaska, where oil output is less than half what it was a decade ago. The fields that since the late 1970s have provided more than 20% of America's oil are slowly running dry. It's a phenomenon that is hardly limited to Alaska. The world's five largest oil companies are replacing only 82% of the oil they pump each year, as once-prodigious fields fade and state entities in such countries as Venezuela and Russia consolidate ever more control over their oil and gas.

The combination of falling reserves and $100-plus oil is sparking a frenzy of oil and gas activity in Alaska the likes of which hasn't been seen since the state's initial oil boom more than three decades ago. ....

Last year the Trans-Alaska Pipeline pumped only a third of its capacity and is set for another 6% decline this year. If the falloff continues, the cost of running the pipeline could exceed its revenues in the next two decades, and it may need to shut down.

www.aspo-usa.com/index.php?option=com_content&task=view&id=311&Itemid=91

Will Alaska Rise Again?

WRITTEN BY ROGER BLANCHARD

MONDAY, 04 FEBRUARY 2008

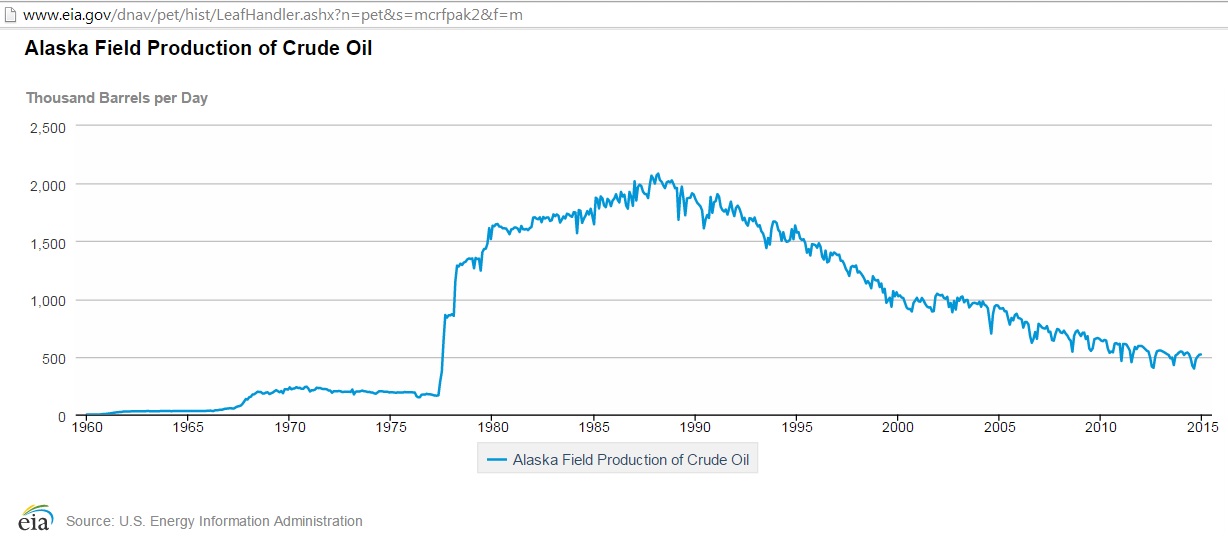

Alaska’s oil production commenced with developments in the Cook Inlet region of southern Alaska in the late 1950s, where production reached a peak of about 220,000 b/d in 1971. Cook Inlet production has since declined to ~15,000 b/d.

The discovery of the supergiant Prudhoe Bay field in 1967 ultimately led to Alaska becoming the top oil producing state in the U.S., at least for a while. In 1977, production started from the Prudhoe Bay field and Alaska’s oil production rose rapidly. The Prudhoe Bay field is the largest field ever discovered in the U.S. and Canada, and one of the twenty largest fields ever found globally. ....

Because the Prudhoe Bay field dwarfs all other North Slope fields, Alaska’s oil production has declined in parallel with the Prudhoe Bay field ....

In the late 1990s, the Clinton administration opened ~4 million acres in the northeast quadrant of NPR-A to oil and gas development. In 2004, the Bush administration opened ~8.8 million acres in the northwest quadrant, although about 2 million acres were deferred for further study. In 2005, the Bush administration opened ~600,000 acres in the Teshekpuk Lake area (northeast quadrant) but the U.S. District Court temporarily suspended leasing. In 2005, scoping started on ~9.2 million acres of the Southern Planning Area of NPR-A for future oil and gas development. ....

To date, no large discoveries have been found in NPR-A and I’m not expecting any. Approximately 0.33 Gb of oil have been discovered and production in the northeast quadrant started in 2006. That new production did not prevent Alaska’s production from continuing to decline in 2007. I believe the most productive part of the NPR-A will be the northeast quadrant and the lack of significant discoveries there does not bode well for the NPR-A contributing significantly to Alaska’s future oil production. ....

What impact would ANWR and NPR-A production have on future U.S. oil production? Figure 4 shows that future production from ANWR, NPR-A and the deepwater Gulf of Mexico would slow the decline in U.S. production out to about 2020 but then production declines rapidly.

The numbers used to calculate future U.S. production will be off to some degree but oil production from ANWR and NPR-A will never cause more than a temporary increase in U.S. oil production. By 2050, domestic production may have fallen below 1 million barrels a day.

One additional factor that may shape Alaska’s oil future is the minimum operational flow through the Trans-Alaska Oil Pipeline (TAPS), which has been estimated at 300,000 b/d. The minimal operational flow limit of the pipeline insures that the ultimate recovery from the North Slope will be less than what could be pumped from North Slope fields before they dry up unless some of the late-stage oil is transported by ship.

New drilling for northwest and northeast Alaska to extend the pipeline's life

Several administrations have sought to open northeast Alaska's Arctic National Wildlife Refuge (ANWR) to drilling. So far, environmental groups have successfully prevented this development, using the argument that "refuges" should be protected from industrial development and citing the critical ecological role this area has for caribou and other species. The Trump administration has pushed again for this, perhaps they will succeed, perhaps not.

Several administrations have sought to open northeast Alaska's Arctic National Wildlife Refuge (ANWR) to drilling. So far, environmental groups have successfully prevented this development, using the argument that "refuges" should be protected from industrial development and citing the critical ecological role this area has for caribou and other species. The Trump administration has pushed again for this, perhaps they will succeed, perhaps not.

Less known is the fact that Clinton Gore opened northwest Alaska to exploration in 1998. This was originally thought to have about ten billion barrels, but more recent estimates project perhaps 800 million barrels (a downgrade of over 90%). The opening of this area had barely a peep of protest from the environmental groups, since the policy was pushed by Democrats and the area isn't called a "refuge" even though it has the same ecology as ANWR.

Neither advocates for more drilling regions nor opponents mention the reason additional areas are sought: Prudhoe Bay is in terminal decline and new sources would extend the usability of the pipeline.

There have also been efforts promoting offshore drilling in the Arctic ocean. However, an early test well called "Mukluk" built a gravel island and was an expensive dry hole. Even if climate change reduces the amount of sea ice, it is likely there will still be some winter ice cover that would make permanent offshore oil wells impossible to maintain (hence the reason Mukluk was on an artificial island). Geologist Colin Campbell estimates there may be more natural gas than oil under the Arctic ocean, but without pipeline capacity or Liquid Natural Gas terminals on the north slope this gas is unlikely to be sent to distant users.

http://nixonisinhell.wordpress.com/2007/08/09/an-inconvenient-truth/

In 1999, Clinton-Gore opened the National Petroleum Reserve – Alaska, (NPR-A), to oil drilling - 24 million acres adjacent to the Arctic National Wildlife Refuge, (ANWR). The NPR-A is an environmentally sensitive area. It contains Teshekpuk Lake, an important nesting ground for many species of migratory bird, including shorebirds and waterfowl. The NPR-A also supports more than half-a million caribou of the Western Arctic and Teshekpuk Caribou Herds. It contains the highest concentration of grizzly bears in Alaska’s arctic, as well as wolverines and wolves that prey on the caribou. NPR-A contains the headwaters and much of the Colville River, Alaska’s largest river north of the Arctic Circle.

Peak Oil Review

Association for the Study of Peak Oil - USA

Vol. 2, No. 41

October 8, 2007

- The North Slope accounts for about 14 percent of US domestic oil production. Its 740,000 b/d is declining about 6 percent a year. One concern of producers is managing the decline of conventional oil production so that there is enough light oil to mix with increasing volumes of heavy oil suitable for shipping through the pipeline.

- BP will begin a heavy oil production test on the North Slope next summer. They will use a technology called cold heavy oil production with sand, or CHOPS, that is being adapted from techniques used with similar heavy oil deposits in Canada. Heavy oil could provide an additional 2 billion barrels from the North Slope.

Dept of Energy - Energy Information Administration - declining Alaska oil production

www.eia.gov/dnav/pet/hist/LeafHandler.ashx?n=pet&s=manfpak2&f=m